Close

- Home

- Products

- Blog

- Sustainable Products

- Contact Us

-

You have no items in your shopping cart.

There are a wide variety of decorating options available. The technique selected will depend on the material to be embellished, the size and detail of the artwork, and the quantities required. Check out some of the more well known decorating options that we regularly use to brand promotional merchandise.

| Decoration Name | Image | Description |

| Digital Transfer |

|

A digital transfer is printed onto a film and then applied through heat to promotional items such as bags and umbrellas. This method allows for full colour, including gradients and allows for a crisper image.

Suitable for: bags, umbrellas & apparel |

| Direct Digital Print |

|

A direct digital print is the process whereby materials are printed on using large format ink-jet printing machines. This print method allows for a full colour print on your promotional items.

Suitable for: Shirts |

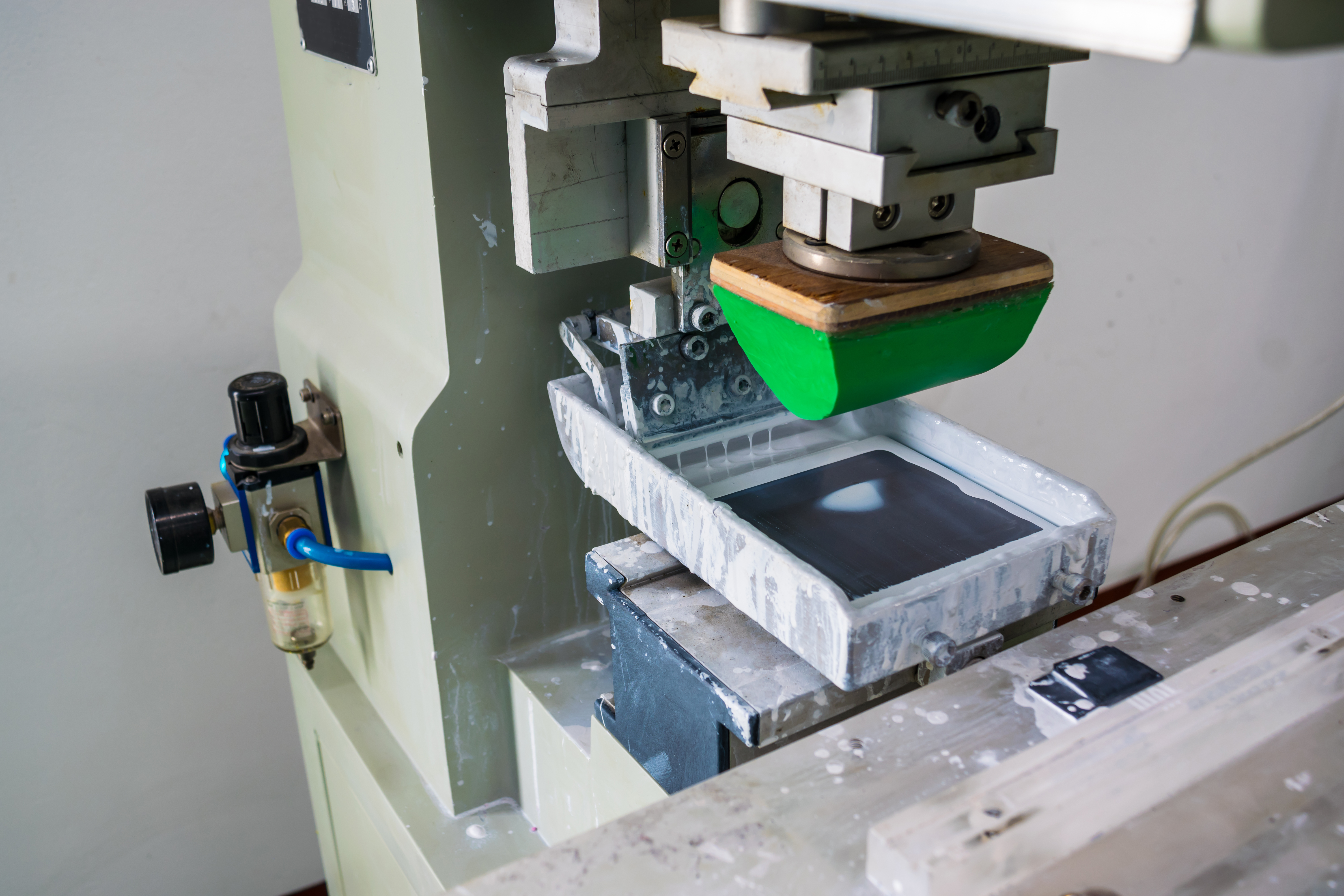

| Pad Print |

|

Pad printing uses a silicon pad to stamp an image onto a product using a laser etched printing plate. This is one of the more popular methods of promotional branding as it is afforadable, can produce larger quantities faster and is best for smaller logos.

Suitable for: foam balls, novelty items & bags |

| Laser Engrave |

|

Laser engraving is a process which engraves artwork into the surface of a product using a laser beam. This print method provides an elegant and simplistic solution to branding, which does not rub off or deteriorate over time.

Suitable for: water bottles, coffee tumblers, metal torches |

| Screen Print |

|

Screen printing is the process of transferring stencilled design, using a mesh screen, ink and a squeegee, onto a product. This method of printing is highly versatile and is best for printing on larger areas, while providing a vibrant finish.

Suitable for: T-shirts, canvas bags |

| Laser Cut |

|

Laser cutting is a mostly thermal process where a focused laser beam is used to vapourize material in a localised area, resulting in a cut edge. The continous cut is produced by moving the laser beam or workpiece beneath it.

Suitable for: Plywood & perspex |

| Emboss & Deboss |

|

Embossing and debossing is the process of using a machine to apply heat and pressure to a product, usually a leather product, to create a pattern or design in the hide. Embossing results in a design that's raised up from the surrounding material, and debossing results in a design that's stamped down or recessed into the surrounding material

Suitable for: leather journals, wallets & luggage tags |

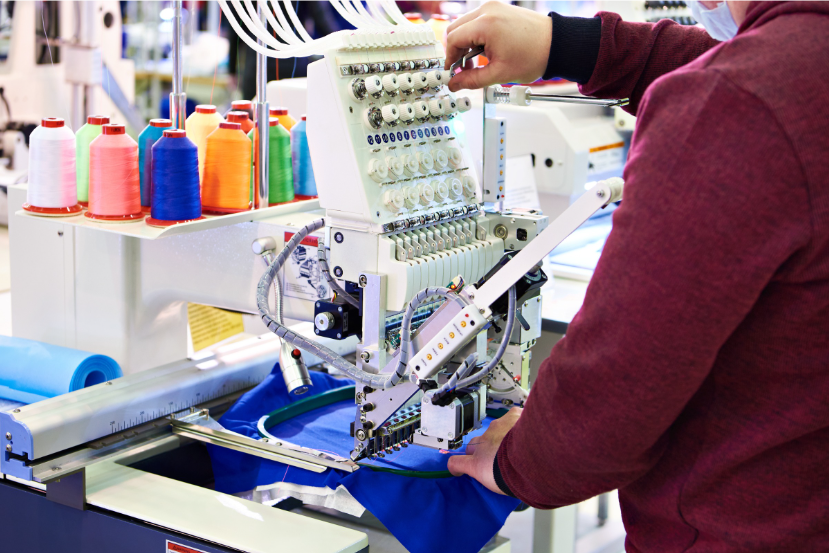

| Embroidery |

|

Embroidery is one of the most desired and popular methods of branding, due to it's durability. This decoration method is achieved using a high-speed computerised sewing machine. A number of heads with needles and thread, pulse the thread back and forth, pushing the thread through the product and backing material creating stitches. The more detail that the artwork/logo has, the more stitches it wil require to be re-created.

Suitable for: Apparel |

Why Decorate?

Decorating your products, whether they be promotional merchandise or client gifts, is a way to make your items special and unique. You can choose to have your logo decorated onto any product using a host of techniques described above. Take it one step further and personalise it with all the names or initials of those who are receiving them. Decorating helps you to promote your brand and your message through products that are fun, functional and trendy.

The Personalisation Appeal